Unparalleled Precision for Complex Composite Structures

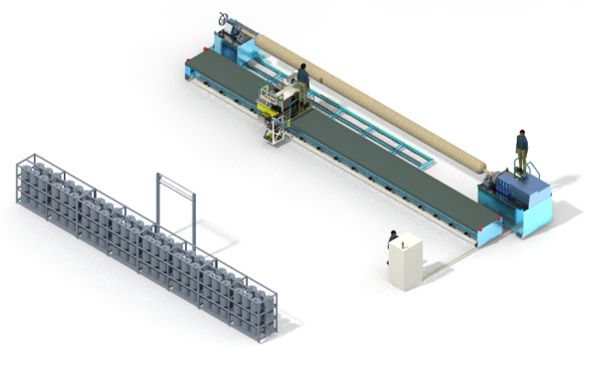

Revolutionizing composite manufacturing processes

X, Y, Z, and U-axis control for superior fiber placement precision

Integrated CNC controller with intuitive MOP for seamless operation

Aerospace, automotive, renewable energy, and more

The pinnacle of innovation in composite manufacturing

Our 4-axis configuration provides unmatched control for complex geometries:

Enables vertical adjustment for precise fiber placement angles relative to the mandrel's axis

Facilitates longitudinal movement of the mandrel, accommodating varying part lengths and sizes

Provides horizontal movement perpendicular to the mandrel axis, allowing for accurate positioning of the winding head

Rotates the winding head around the mandrel axis, enabling application of fibers at multiple angles for intricate geometries and tailored fiber orientations

We specialize in designing and manufacturing cutting-edge filament winding machines tailored to meet the demands of modern composite manufacturing. Our 4-axis filament winding machine represents the pinnacle of innovation, offering unparalleled precision and versatility in producing complex composite structures.

Versatile solutions for diverse industries

Rocket motor casings, aircraft fuselages, structural components

Drive shafts, suspension components, chassis parts

Pressure vessels, storage tanks, pipes, rollers

Wind turbine blades, poles, nacelle components

Why choose our 4-axis filament winding solution

Advanced 4-axis control enables precise fiber placement for complex geometries and optimal structural integrity.

Automated processes reduce production time by up to 40% while maintaining consistent quality standards.

Quick-change tooling and adaptable configurations allow for rapid transitions between different product types.

Discover how our 4-axis filament winding machine can optimize your production process and deliver superior composite components.